TYPES OF BOARDS

Scaffolding Boards:

Steel board, Aluminum, and Timber are three main types of scaffolding boards.

lvl board

aluminum board

steel board

SCAFFOLDING BOARDS

Almost all scaffold boards are manufactured from pine and seasoned wood. The boards must comply with BS 2482, Specification for Timber Scaffold Boards This specifies the type of timber that can be used in the manufacture of scaffold boards and prescribes a test method for assessing them. Bending strength

Wood planks come in three thicknesses. 38 mm, 50 mm, and 63 mm. and generally 225 mm wide and 3.90 m long. Smaller boards are used when necessary. The most common board is 225 mm * 38 mm.

Boards (BS 2482 )

STEEL DECKING AND LAMINATED BOARDS.

A number of firms market staging that is either made of steel or aluminum, or laminated boards that can be used in conjunction with proprietary scaffolding systems. These come in various widths Safe spans are listed in the manufacturer’s literature and timber products must comply with BS 1129, Timber or light-weight staging for ladders, steps, trestles, and industrial, portable aluminum ladders, steps, trestles, and use Lightweight stages include up to 2037,

laminated boards

steel decking

Identification of Boards

Each board should be identified by clearly marking the following information:

British Standard Number (BS 2482)

The identification mark of the supplier

A machine or visual classification indicating the letter M or V

The word, support, is followed by the maximum Spain in meters at which the board is to be supported followed by the abbreviation Max, eg BS 2482 AB Co.M Support 1.5 Max.

This is usually given on a band or nail plate, which provides protection to the end of the board, alternatively, a special identification plate may be branded on the board.

Many boards in use do not comply with BS 2482.

These should be supported every 1.2 m ( marked on board )

INSPECTION AND MAINTENACE

Care should be taken with the boards in use. Not much, pressure should be allowed, eg. This is due to impact loading. Boards should not be used as ramps or platforms over long distances, nor should they be placed where vehicles or other loads can be placed on them. For example, tire tracks should be destroyed.

Scaffold boards must be cleaned and bands or nail plates secured or replaced, split boards can be cut or repaired using nail plates depending on the degree of damage. No cutouts, burns, oil stains, or protruding nails should be present.

The boards shall not be painted or treated in any manner that may conceal defects but may be fireproofed using approved materials.

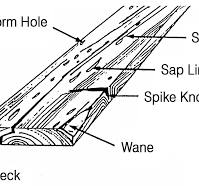

COMMON FAULTS

. Cracked.

.Split. Worn and cut

. Warped. Vehicle loaded

. Excessively knotted. Rotten Planks.

SCAFFOLDING STORAGE

Scaffold boards should not be placed more than 20 feet high, with small wooden bills, and should be placed on surface timbers off the ground to protect against surface water, boards should be protected from weather and free circulation of air.

scaffolding storage area

0 Comments